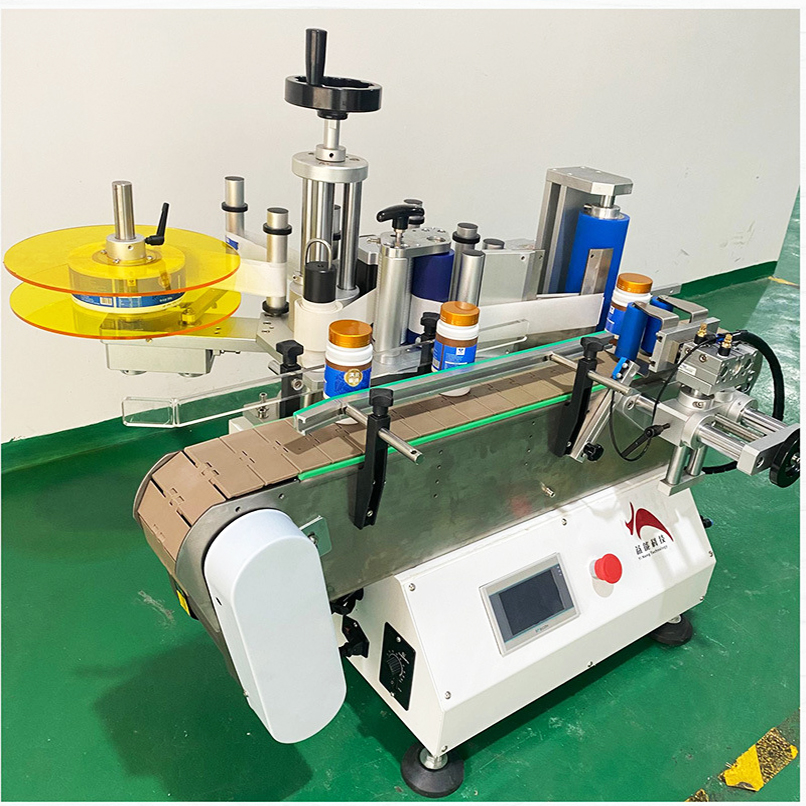

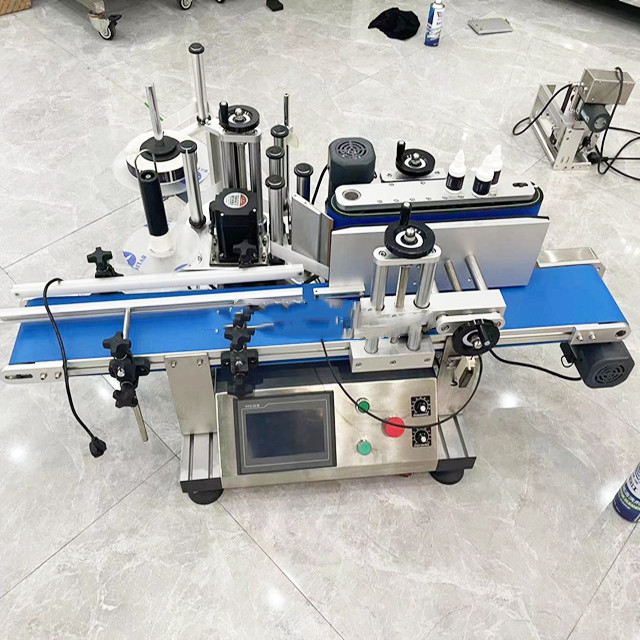

Tabletop type round bottle positioning and labeling machine is suitable for positioning and labeling various specifications of cylindrical or conical products, and is widely used in cosmetics, food, medicine, daily chemicals, toys, hardware, plastic, and other industries. It can achieve full/half cycle labeling, and circumferential front and back labeling.Characteristic:

1. Color touch screen control, intelligent operation, Chinese and English optional operation interface;

2. A wide range of applications, with multiple uses and easy adjustment for one machine, making it easy to operate. Different bottle sizes do not require replacing components, but only adjusting the machine.

3. PLC intelligent control, stable operation, logic calculation, timing and other functions, strong anti-interference ability, and complete functions. PLC also has hardware fault self detection function.

4. Automatically locate the labeling position. The device detects the product’s passing and transmits a signal to the labeling control system. At the appropriate location, the system instructs the corresponding motor to send out the label and affix it to the position where the product is to be labeled. Single label, double label, front label, and back label are available. The label spacing can be adjusted, and can be affixed in full circumference or half circumference.

5. Imported marking eyes, durable, electronic eye sensing detection, no labels, no products, no hot work for a long time, to ensure the normal operation of the machine labeling.