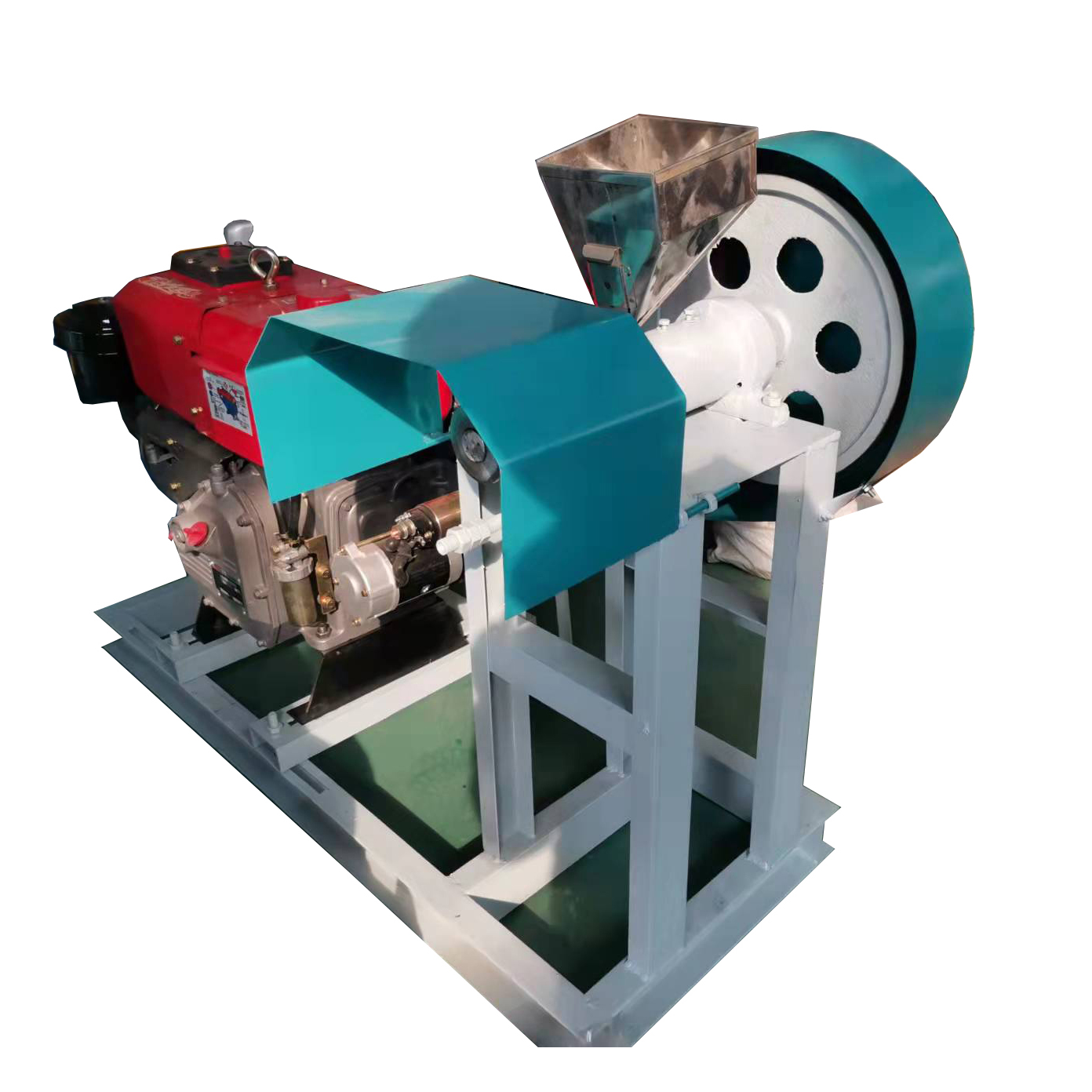

Small Floating Fish Feed Extruder Machine Line with Factory Price

Working Process of fish feed processing line

Technological procedure:

Raw materials → mixing → conveyor → extrusion puffing → conveyor → drying → cooling → screening → spraying oil →seasoning → packaging

Equipment configuration:

Mixer → conveyor→ extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging

Technical parameter:

Main Machines | Power | Capacity | Remark |

Feed Hammer Mill | 5.5kw | 200kg/h | The hammer mill is mainly used to pulverize several items such as oil seed meal,corn, beans, wheat, and other materials into powder. |

Powder Mixer | 4kw | 25kg/batch | The mixer machine is mainly be used to mix all kinds of raw material evenly, such as wheat meal, corn meal,sorghum meal,bone meal,meat meal and so on. |

Feed Extruder | 15kw | 100-150kg/h | It is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc and animal feed for cat,dog, cotton, chicken and so on. |

Dryer | 15-18kw | 150-200kg/h | Final pellets from fish feed extruder are moist in high temperature, so they can not be transported and stored immediately and require to be dried first. |

spraying machine | 0.75kw | 25kg/batch | Final pellets from fish feed extruder are moist in high temperature, so they can not be transported and stored immediately and require to be dried first. |

Write your message here and send it to us